Raw metals are the backbone of modern industries—from construction and automotive to electronics and aerospace. The United States plays a crucial role in supplying these essential materials worldwide through its network of advanced metal mills. But how exactly do U.S. mills operate to meet global demand? Let’s explore.

What Are U.S. Metal Mills?

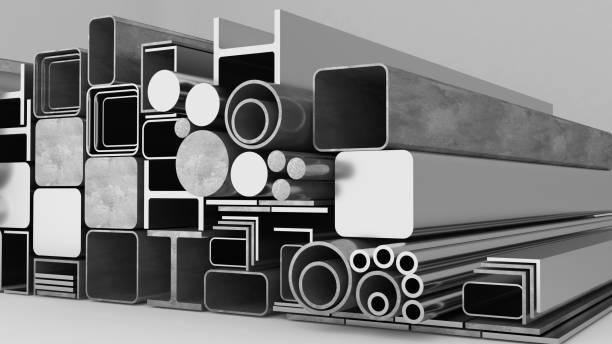

Metal mills are industrial facilities that process raw ores or recycled metals into usable forms like sheets, bars, rods, or coils. In the U.S., these mills specialize in various metals including:

- Steel

- Aluminum

- Copper

- Nickel

- Titanium

These mills employ cutting-edge technology and strict quality controls to ensure their products meet international standards.

The Supply Chain: From Mills to Global Businesses

1. Raw Material Sourcing

U.S. mills source raw materials domestically and internationally. This includes mining ore from American mines or importing scrap and ores from countries with rich mineral deposits.

2. Processing and Manufacturing

Once raw materials arrive at mills, they undergo melting, refining, and shaping processes. Modern mills use energy-efficient furnaces and automation to produce metal products that meet precise specifications.

3. Quality Assurance

Before shipment, metal products are rigorously tested for strength, purity, and durability. Certifications like ASTM and ISO help assure global buyers of consistent quality.

4. Distribution & Export

After production, metals are transported through a well-coordinated logistics network—rail, truck, and port facilities—to reach manufacturers worldwide. U.S. mills have long-term contracts with global businesses, ensuring steady supply even during market fluctuations.

Why Global Businesses Trust U.S. Mills

- Reliability: U.S. mills have a reputation for timely deliveries and consistent quality.

- Innovation: Adoption of modern tech like AI, robotics, and data analytics improves efficiency and product standards.

- Sustainability: Many mills invest in eco-friendly practices, recycling scrap metals and reducing carbon footprints.

- Regulatory Compliance: Strict adherence to environmental and safety standards builds trust with international clients.

Key Industries Relying on U.S. Metal Mills

- Automotive: High-strength steel and aluminum for lightweight vehicles

- Construction: Structural steel beams and copper wiring

- Aerospace: Lightweight titanium alloys for aircraft parts

- Electronics: Copper and aluminum for circuits and components

- Energy: Metals for pipelines, wind turbines, and solar panels

Looking Ahead: Challenges and Growth Opportunities

U.S. metal mills face challenges such as fluctuating raw material prices, international competition, and stringent environmental regulations. However, investments in smart manufacturing and green technologies provide opportunities to maintain competitiveness and meet increasing global demand sustainably.

The Essential Role of U.S. Metal Mills in Global Industry

By combining technological innovation, sustainability, and reliable logistics, U.S. mills continue to be vital partners to global manufacturers. Their ability to supply high-quality raw metals keeps industries running smoothly around the world—making them an indispensable part of the modern supply chain.